Countertop Automation

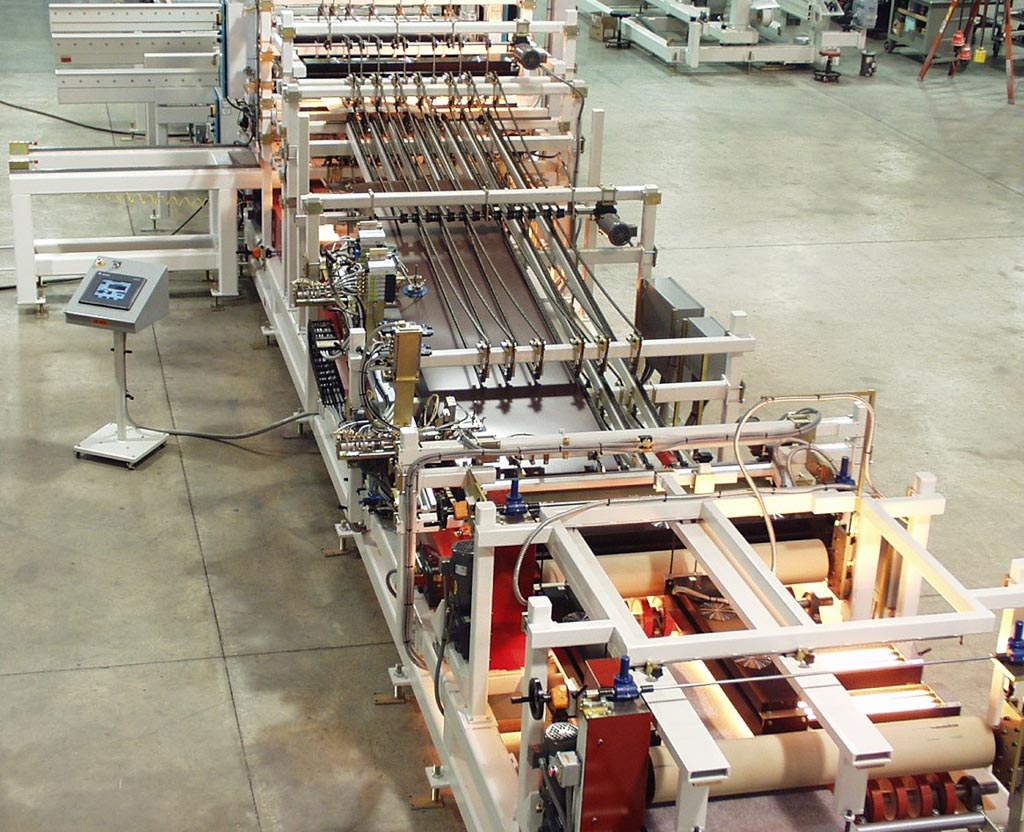

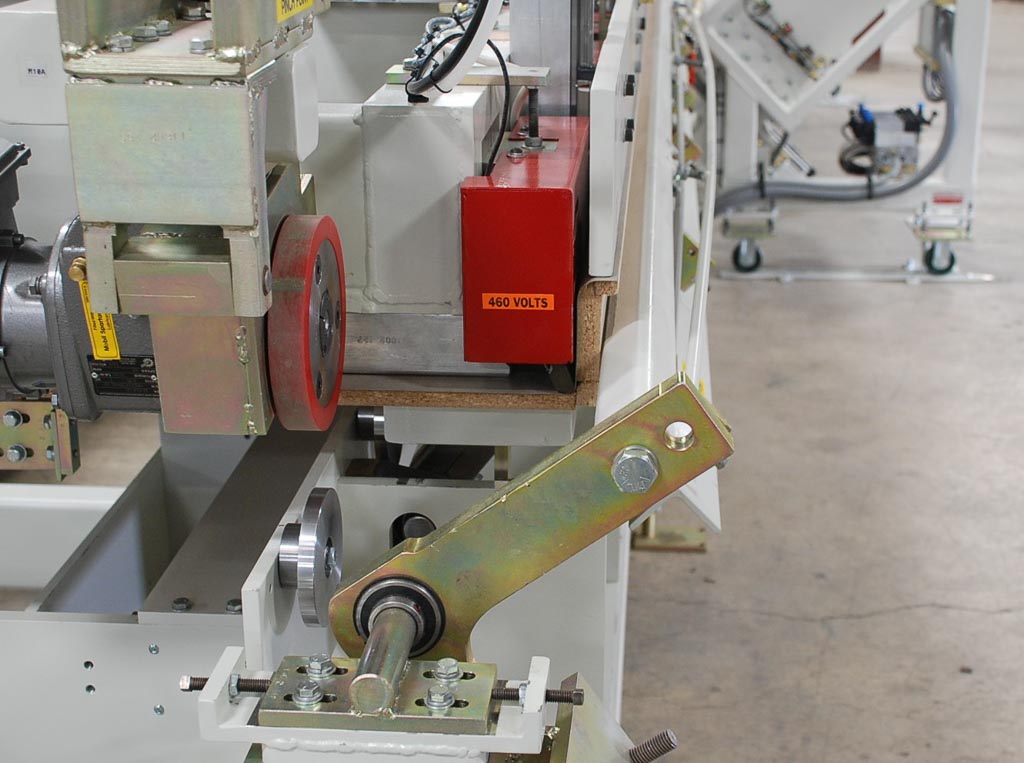

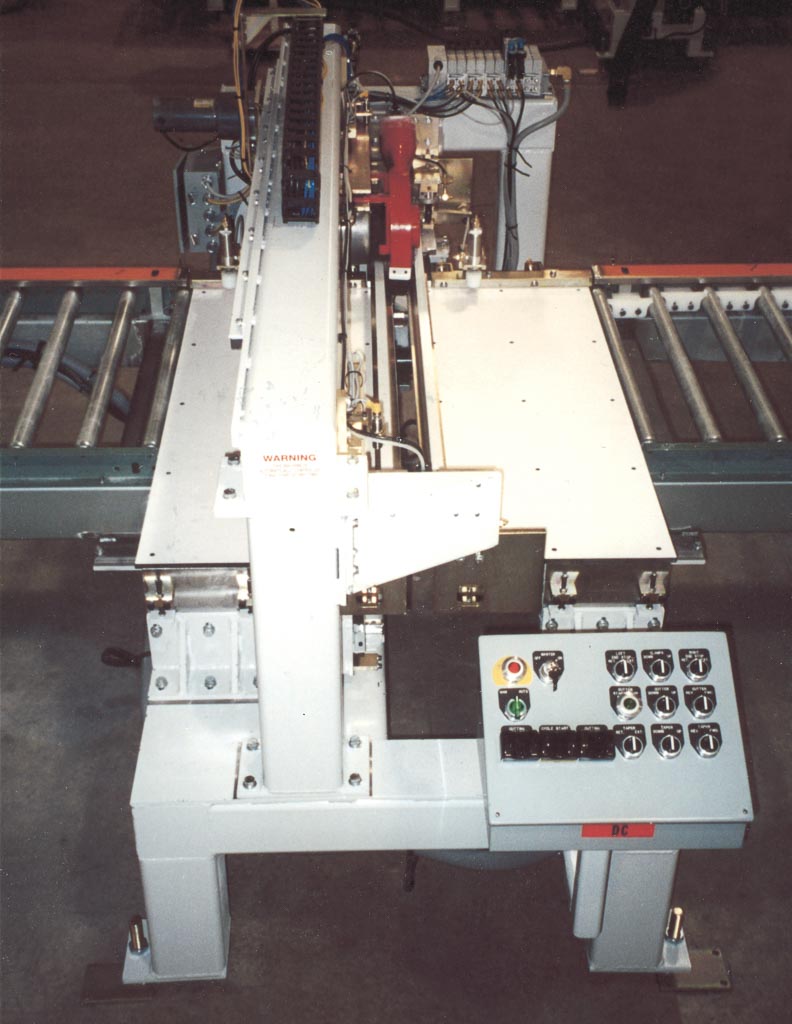

Laminate

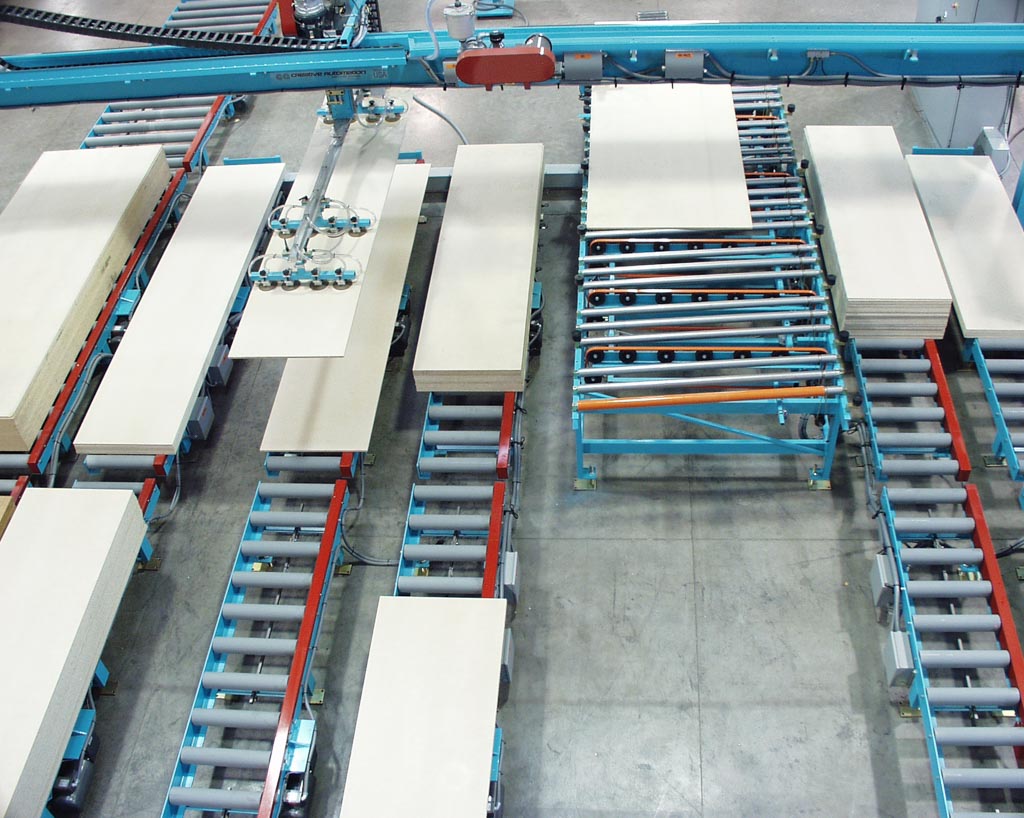

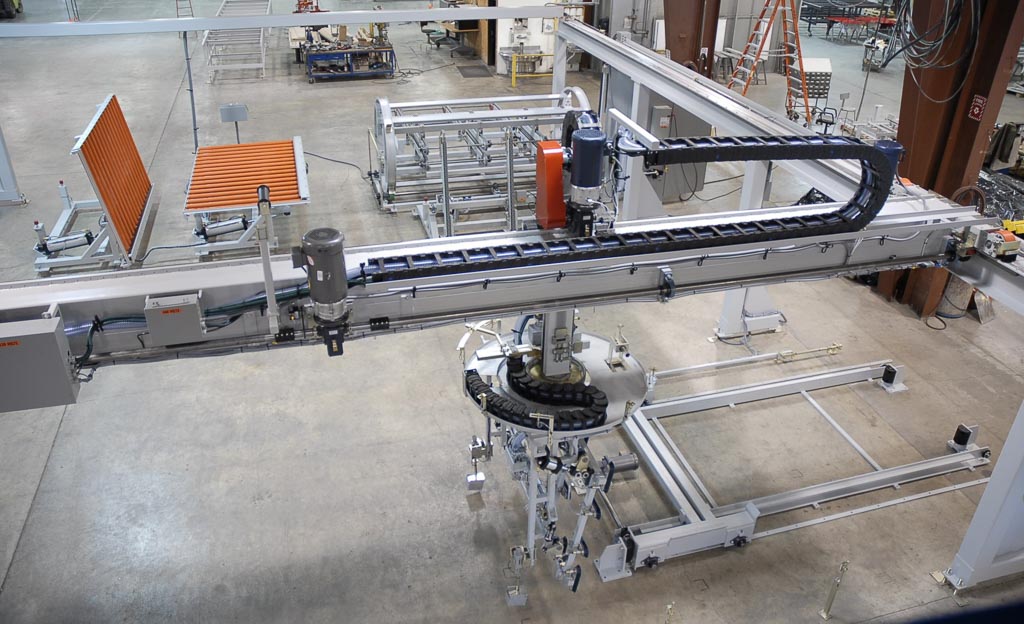

At Creative Automation, we handle virtually every aspect of countertop automation and manufacturing. Following are examples of some of the custom solutions we have provided to the industry.

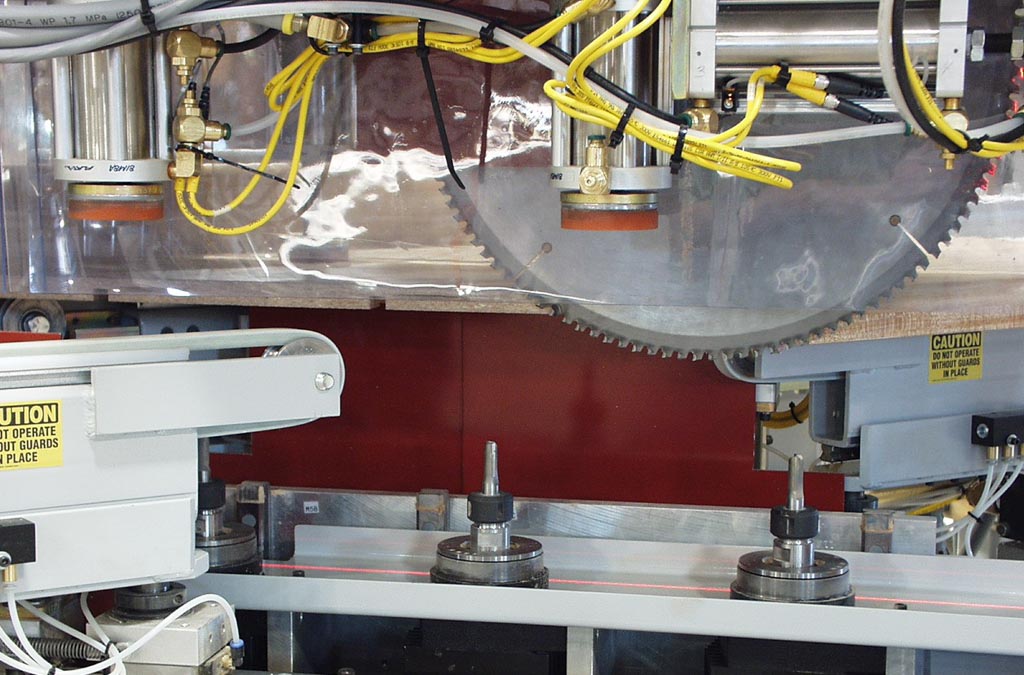

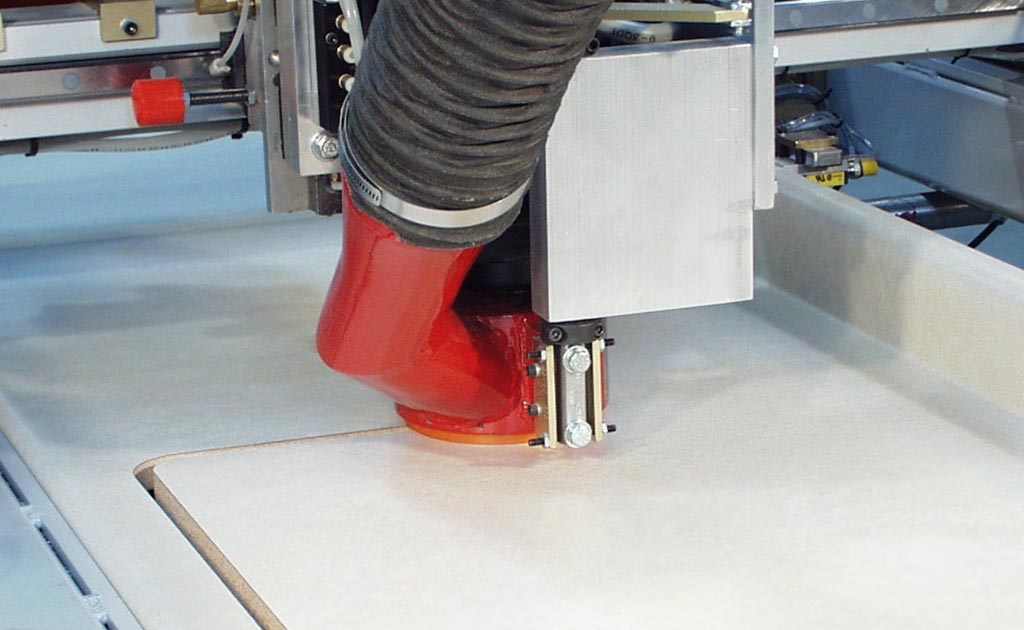

Solid Surface

Creative Automation provides automated solid surface countertop solutions for the kitchen and related industries