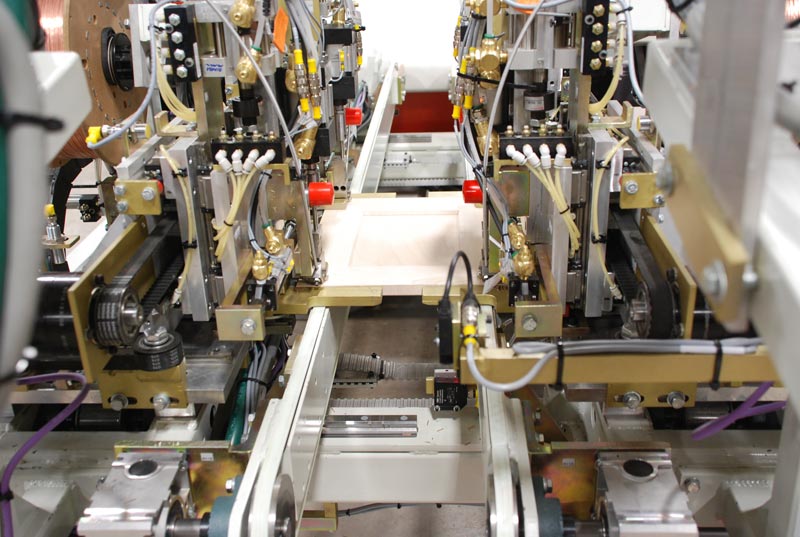

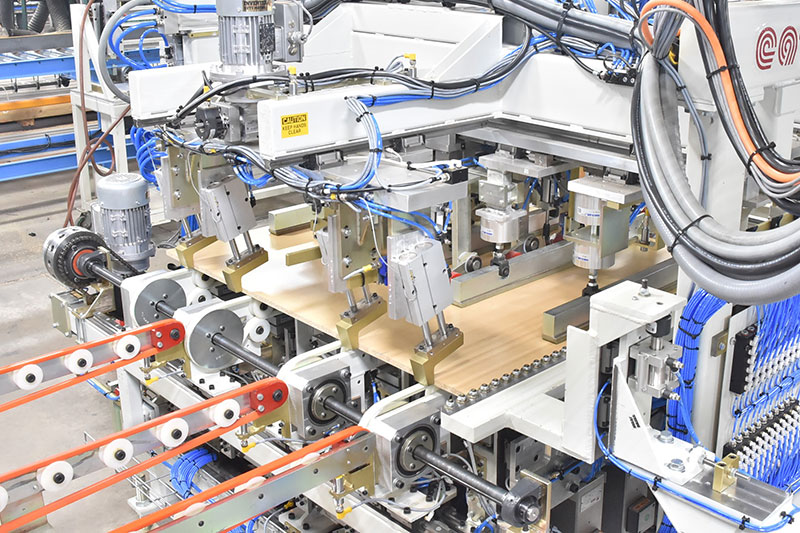

Automated Processing Equipment

“We Remain our Customers’ First Choice because of our Practical Engineering, Rugged Construction, Extensive System Integration and First-Rate Support.”

Custom Designed and Manufactured Automated Processing Equipment

Fifty percent of our production is custom processing equipment for all types of the wood and related industries. As always, all our work is custom-engineered for optimal performance and longevity, and is a perfect companion to our material handling offerings.

Automated Processing Capabilities Include:

Let Creative Automation help with your production application! We are accustomed to engineering prototype, custom, and other one-off equipment.

Specialty processing makes up 50% of our annual volume, and our engineering teams are well-versed at tackling challenging tasks

Call us today to learn why we say, “If a system can be conceived, Creative Automation can design and build it!”