Learn About Creative Automation

Creative Automation – 50 Years in Business

Over the last 50-plus years, the Creative Automation story has been built with innovation, grit, and collaboration. We have a rich history in automated material handling and processing equipment for the wood and related industries. This is our story…

Creative Automation – 50 Years in Business

Our History

Creative Automation has designed, built, and installed well over 4,000 custom machines for the wood and related industries. Facility is now 14-times larger than the original structure.

We expand our CNC capabilities with new Viper PMX-6127, which boasts a 50,700-lb load capacity, fully automatic right-angle head to enable machining on all 5 sides, 20-ft x 7-ft table size, and 60-tool automatic tool changer.

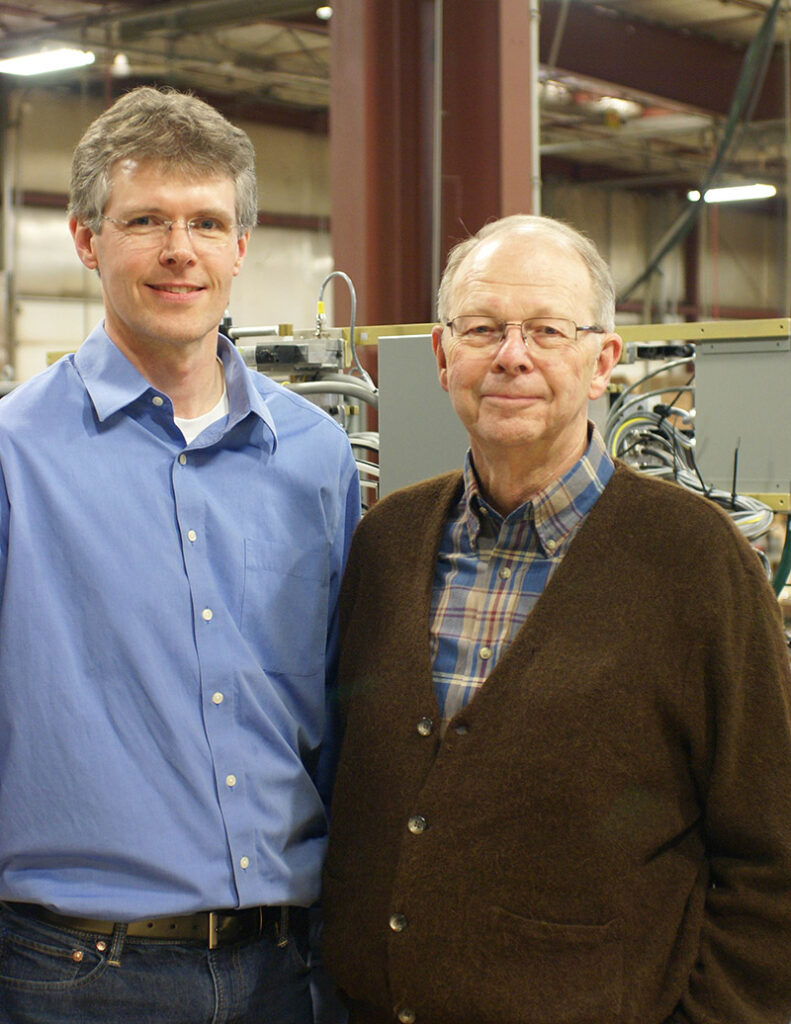

CA celebrates our 50th anniversary. Pictured are Tom Streckert, founder and President, and Sondra Streckert, VP and Corporate Secretary. Retired, Sondra has enjoyed assisting with the company’s scholarship program.

Acquired new Mori 4-axis horizontal machining center, increasing efficiency in making certain machine parts. Boasts a 60-tool automatic tool changer.

We celebrate our 40th anniversary with an airplane-themed cake, reflecting our founder’s longtime passion for aviation.

Quickmill CNC machining center is installed. It weighs over 100 tons, boasts a 44-ft x 12-ft table size, and tackles many of our largest parts.

Large Komo CNC machining center is purchased at the end of the year. Second Komo CNC is purchased shortly afterward, adding to Creative’s formidable machine shop.

CA becomes one of the first companies in the woodworking industry to install modems on machines, enabling engineers to dial up a machine from our office to assist the customer with troubleshooting and program changes. Today we access our machines remotely with a VPN connection.

The first portable computer—“portable”being used loosely—is purchased for PLC programming. It is made by Compaq and has a 10MB hard drive.

Word processing is implemented in the office with software called WordStar. It is run on an IBM XT computer that has 10MB of hard disk space.

Scholarship program begins to benefit local high school seniors and award employee dependents.

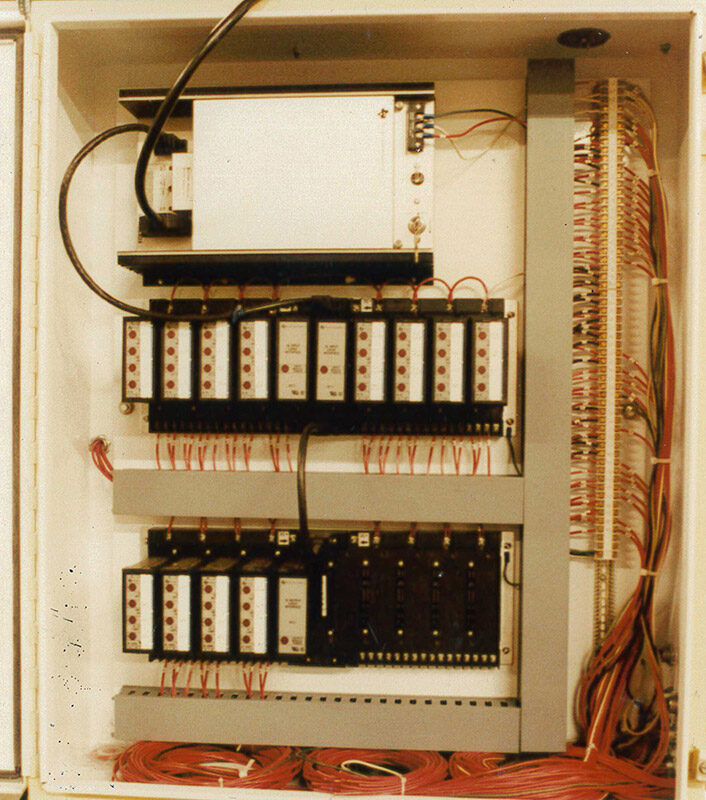

The first machine with a programmable logic controller (PLC) is installed. Early PLCs are programmed with a hand-held keypad.

First full-time employee hired.

Because there were no computers or PLCs available at the time, Tom designs and builds his own circuit boards. These are for Stacker/Feeder control logic systems.

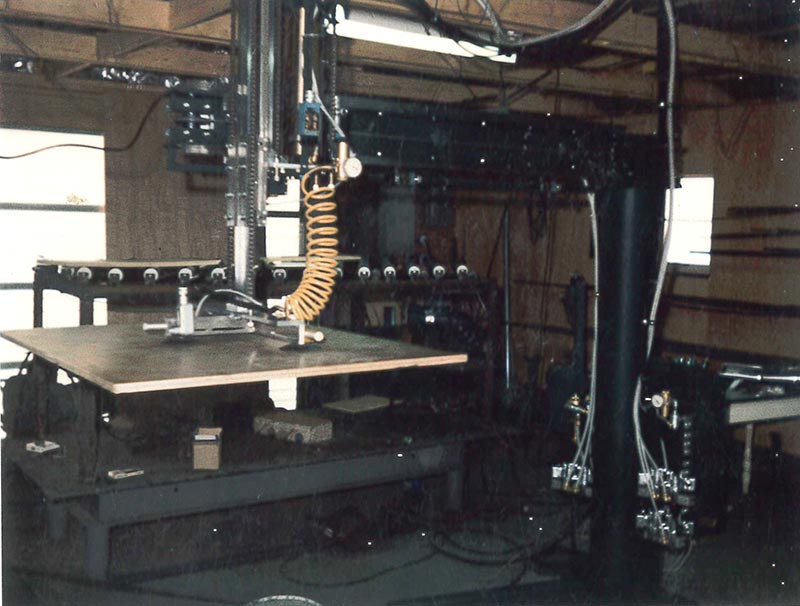

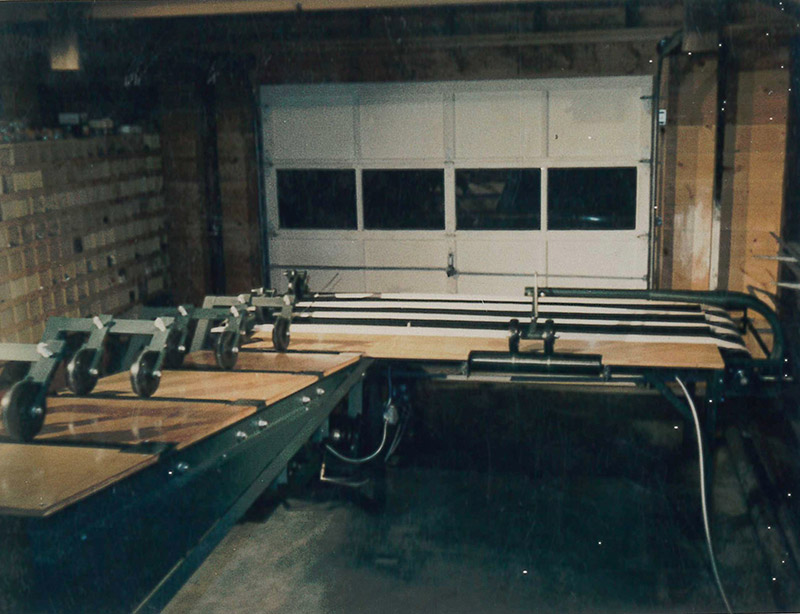

First Stacker/Feeder is built in the garage – over 400 custom Stacker/Feeders have been installed since then.

Tom Streckert registers the corporation with the State of WI, building machinery in the family garage. Sondra Streckert—Tom’s wife and confidant—coins the name “Creative Automation”.