Layup Lines

Fully Automatic Layup Lines

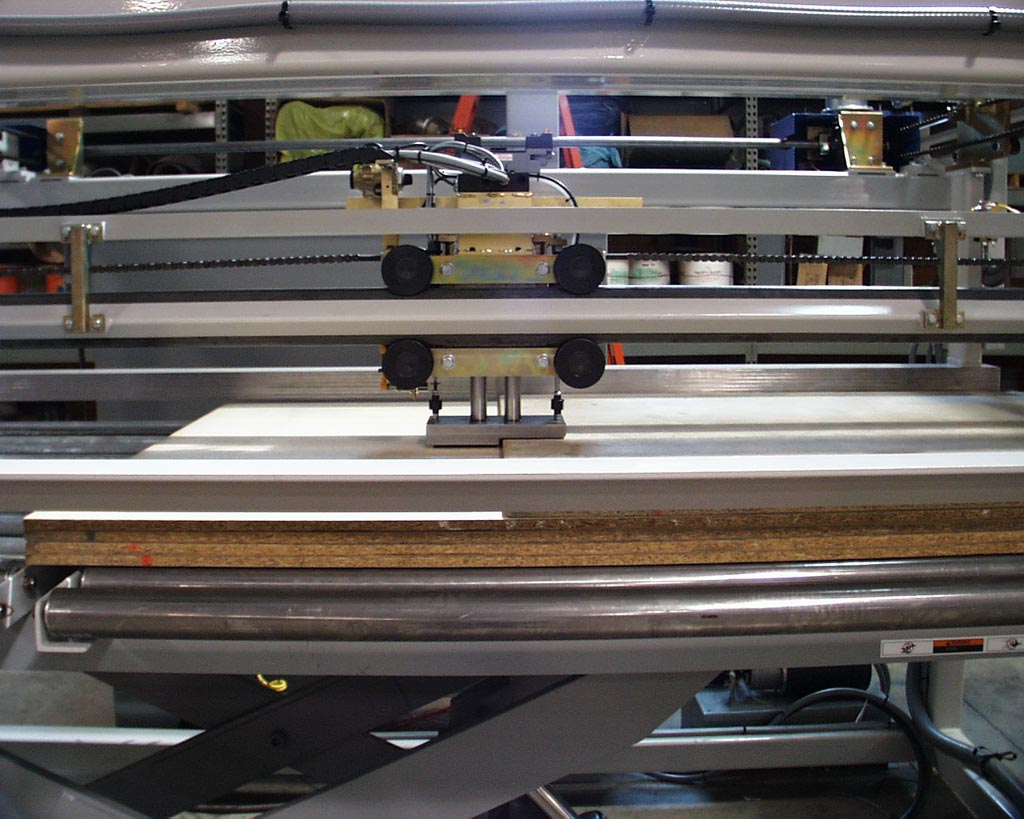

Creative Automation provides custom automatic layup solutions for hot and cold press lines.

These systems are ideal for layup of doors, panels, etc. Layup and supporting material handling equipment is integrated with the customer’s choice of press and other necessary processing equipment.

Following are examples of two layup lines, one for door production, the other for laminated panels.

Custom Door Layup Line

Creative Automation designed and built a full complement of automated material handling equipment to link the following processing equipment together: sander, panel cleaner, gluespreader, multi-opening hot press, and double end tenoner. The system was designed to lay up cores with veneer, laminate, and crossbands at a rate of four doors per minute. Cores can be handled up to a maximum door weight of 750 lbs.

Following are descriptions of select equipment in the line.

Custom Panel Layup Line

Creative Automation designed and built a full array of automated material handling equipment to integrate with a feed through hot press. The system was designed to layup cores with laminate coming in precut sheets or automatically cut from rolls. Laminate types handled were: melamine, polyester, phenolic, and backers. Laid up cores were static charged to keep them aligned prior to pressing.

Semi-Automatic Layup Lines

Semi-Automatic layup solutions increase throughput and consistency. This specific solution lays up for a cold press and features fully automatic core feeding, gluing, and stacking. Laminate is hand placed.